There are numerous consequences of inadequate risk monitoring. Sphera conducted a survey in 2025 and found that 60% of companies encountered at least one serious supplier-related disruption in the year before. The repercussions were so severe that many companies suffered losses of a minimum of 8% of the total revenue.

Traditional solutions offer assessments that are not sufficient today. The business environment is marked by volatility and faster-than-light modern risk developments.

Being so, the subsequent question is: Is your current supplier risk monitoring solution missing critical changes? If so, how do you address these gaps?

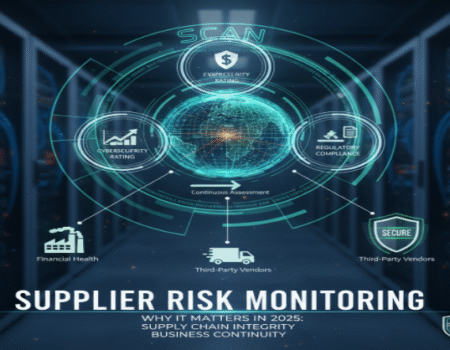

What is supplier risk monitoring and why does it matter in 2025?

Supplier risk monitoring is the systematic tracking and evaluation of potential risks.

Third-party vendors are connected to these risks to secure supply chain integrity and business continuity. This kind of risk monitoring instills confidence because it provides a continuous assessment of suppliers’ financial health, cybersecurity rating, and regulatory compliance lapses, and third-party data breaches. It also evaluates compliance with standards like ISO 27001, SOC 2, GDPR, and HIPAA.

Have the supplier ecosystems evolved?

Yes, the supplier ecosystem has developed. In fact, the earlier approach was dangerously vulnerable to disruptions—as exposed through recent global changes. Now, the primary focus isn’t cost minimization and just-in-time inventory management only.

One major complexity is the ongoing interdependence of suppliers, manufacturers, logistics providers, and retailers.

Another important change permeated in the late 1990s when import dependencies steadily rose, affecting international trade.

One of the research directors at Gartner, Chris Audet, emphasizes that an iterative approach to third-party risk management (particularly, as hidden supply chain risks) is imperative because of the constant changes.

Why real-time visibility is now essential

Real-time visibility transforms decision-making because it provides immediate and actionable data. As a result, predictive supplier monitoring helps organizations benefit better, as they have information regarding cargo location and shipment conditions. This upgraded visibility limits downtime, keeps a check on excess inventory, and creates up-to-date audit trails.

Meanwhile, companies can also simulate disruption scenarios using available information and create contingency plans. This understanding prepares companies to face various possibilities.

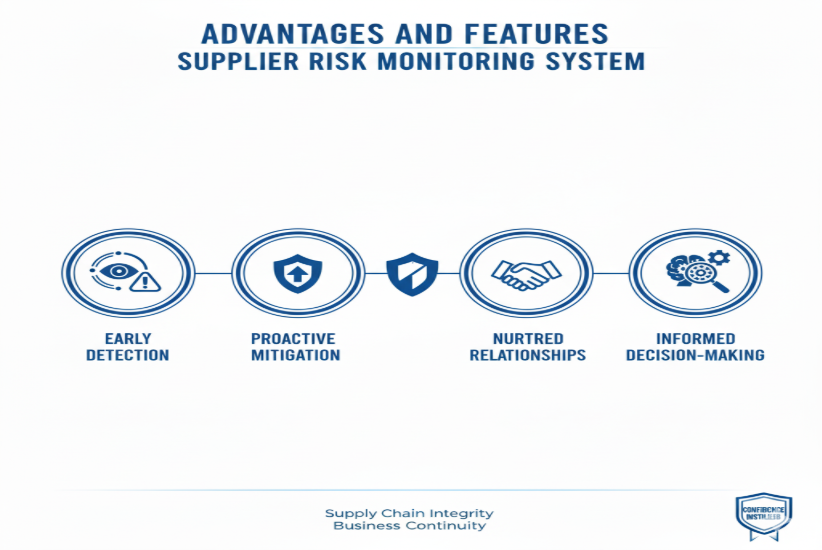

Advantages and Features of a Supplier Risk Monitoring System

Here are the advantages of an effective supplier risk monitoring system:

- Early risk detection–spot potential threats before they expose themselves during scheduled assessments.

- Proactive mitigation–major issues (supply chain disruptions or production halts) can be averted before they erupt into major disruptions.

- Enhanced supplier relationships–risk monitoring nurtures collaborative partnerships.

- Improved decision-making–knowledge of current risk information helps strategize.

Below are the features of an effective supplier risk monitoring system:

Real-time alerts and continuous scanning

Modern monitoring systems continuously scan multiple data sources. Whenever there is a security issue, this real-time data scanning notifies teams automatically; along with these, they also provide severity reports and suggest mitigation steps. The supplier risk monitoring solution discovers early-stage threats through this ongoing process.

Automated risk scoring and tiering

AI-driven assessments and scoring mechanisms make risk monitoring platforms sophisticated. Users can also customize scoring frameworks according to requirements. These risk monitoring solutions can categorize suppliers into tiers based on criticality, enabling proportional monitoring. That is, high-risk vendors receive more attention while maintaining appropriate supervision of lower-risk partners.

Integration with internal systems

Often, sources of data are fragmented and disparate. But, monitoring platforms can effectively integrate with internal systems via APIs, bringing uniformity across procurement, finance, compliance, and operations.

This API-based system integration helps organizations track supplier performance against agreed SLAs and KPIs. Automatic workflows notify stakeholders when risks cross tolerance levels or performance dips.

Fourth-party and sub-tier visibility

Most of the time, direct suppliers are not the only cause for vulnerabilities in a supply chain. To identify hidden sub-tier supplier dependencies and risks, organizations must have visibility into suppliers of their suppliers (fourth parties).

In such cases, organizations can discover critical connections that might otherwise using advanced monitoring systems.

Regulatory compliance tracking

To ensure compliance, supplier risk monitoring systems should identify vendor alignment with frameworks like HIPAA, SOC 2, and ISO 27001.

A real-time compliance monitoring tool collects compliance data continuously. It also alerts managers about non-compliance events such as expired certifications. In this way, organizations reduce manual effort and maintain compliance at the same time.

Types of supplier risks you might be missing

As mentioned above, there are many threatening vulnerabilities hiding within supplier networks. But many organizations focus on direct threats and overlook these. Let’s see the hidden risk in our business:

Cybersecurity vulnerabilities

Presently, we are seeing attackers targeting suppliers as indirect entry points, and this strategy has produced results that are alarming. In 2024, there was a 43% year-over-year increase in data breaches with 2.9 billion unique sets of compromised credentials leaked. The MOVEit Transfer incident illustrates third-party data breach; A single vulnerability in this file transfer tool caused a major supply chain attack that affected more than 2,700 organizations and exposed data from over 93 million individuals.

Compliance and legal risks

The ongoing changes in data localization laws, cross-border restrictions, and sanctions sometimes compel long-standing supplier relationships non-compliant. This is more challenging when suppliers operate in different regions with varying standards.

Operational and continuity risks

Surprisingly, 45% of organizations experienced third party-related business interruptions in the last two years.

The common warning signs are:

- Poor compliance management

- Minimum or no oversight of fourth-party vendors

- Imbalanced sales versus business tenure

- Many sectors are completely dependent on a small number of highly specialized suppliers for services, meaning a disruption affecting one provider can have disproportionate consequences.

Reputational damage from third parties

Operational threats, including data breaches, supply chain disruptions, financial instability, and regulatory non-compliance can cause reputational damage.

These risks are more in third-party relationships where visibility and control are often reduced, when networks extend into fourth or nth-party subcontractors.

Gainfront’s Potential Contribution

Though many organizations have understood the importance of supplier risk monitoring, they still continue to face challenges. This is because their traditional systems capture data but do not help in eliminating risks before they mount up.

However, Gainfront, powered by EfficiencyAI™, combines Generative AI and Agentic AI in one platform that learns, predicts, and acts autonomously to reduce disruptions and strengthen supplier ecosystems. Gainfront delivers both AI-driven supplier risk management and autonomous risk mitigation.

| Challenge from the Analysis | Gainfront’s Potential Contribution |

| Inadequate, Periodic Assessments | Real-Time Alerts and Continuous Scanning: Gainfront uses EfficiencyAI™ to monitor multiple data sources continuously. It also offers real-time alerts and early risk detection. |

| Need for Scalable, Proportional Monitoring | Automated Risk Scoring and Tiering: Gainfront automatically scores and categorizes suppliers based on criticality through its AI-driven assessments. |

| Fragmented Data and Lack of Actionable Insights | Integration with Internal Systems: Gainfront integrates with internal systems via APIs and brings together data from procurement, finance, and compliance. |

| Hidden Fourth Party/Sub-Tier Risks | Fourth-Party and Sub-Tier Visibility: Gainfront’s advanced AI-driven monitoring extends visibility beyond direct suppliers. |

| Managing Evolving Regulatory Demands | Regulatory Compliance Tracking: Gainfront tracks, using DocVault, supplier alignment with standards such as HIPAA, SOC 2, and ISO 27001 continuously. |

| Cybersecurity Vulnerabilities | Continuous Risk Monitoring: Gainfront always scans for issues such as compromised credentials and security vulnerabilities. |

Case Study: Preventing a Production Halt

A leading automotive manufacturer implemented our real-time supplier monitoring Gainfront solution. After implementing, EfficiencyAI™ found out signs of financial instability in a Tier-2 supplier; it automatically alerted procurement leaders. As a result, the client saved millions from potential losses by preventing a six-week production delay.

Testimonial

“Gainfront helped us prevent supplier problems. Gainfront’s AI-driven solution helped us see risks before they became disruptions.”

— Chief Procurement Officer, Global Pharmaceutical Enterprise